single solenoid valve

arv valve

Valves are mainly used in industries for different types of applications. They can be used in most commercial, and residential industries. Due to a variety of uses, there are several major rules and regulations when using these types of valves to ensure proper functionality and most importantly the safety of users.

These valves play a big role in controlling the flow of fluids and gas in pipes. There are different standards used in industrial valves, today we are going to put more attention on API 6D valves. Read on

Table of Contents

API 6D

What Is API 6D?

Source: https://www.pinterest.com/pin/836543699524629322/

The API 6D is the most preferred specification majorly for the Pipeline Valves. It is the main standard according to the ISO 14313 that defines the condition of valves and provides suggestions for the design, manufacture, inspecting, and documentation of different valves including check, ball, plug, and gate valves in piping systems.

API 6D Standard

Source: https://en.siovalve.com/

API specifications are the best practices developed based on observation extracted from the petroleum and petrochemical industry that is reasonable given that API stands for American Petroleum Institute. API standards are meant specifically to encourage safety in the oil and natural gas industries. American Petroleum Institute standards allow you to Improve and have excellent operations and also ensures compliance and safe practices.

API 6D Testing

Source: https://www.pinterest.com/pin/362539838758552806/

Do you have some spare valves in your store that you are planning to fix on your pipeline? If that is true, when was the last time those valves were tested to API 6D specifications? If you are in the field of oil and gas, definitely you are very familiar with API 6D.

It is the standard that provides specifications for ball valves, check valves, gate valves, and even plug valves used mainly in pipelines. American Petroleum Institute API 6D testing is a requirement by the transportation department for all valves in the pipeline. So that in case of any occurrence of an accident,

Not only is API 6D testing a requirement of the transport Department for all pipeline valves, but also important to both the department of transport (DOT) and the Environmental Protection Agency (EPA). In case of an accident occurring they will want to review the test records of the valves to assess whether your valves are in compliance with the testing protocol.

Common Conditions When You Will Have To Test Your Valves

When you are recommissioning a pipeline. Over the recent past, pipelines that were shut down have started being recommissioned. Since the valves on these industries have been idle for years, there is a need for them to be repaired and tested.

When you are fixing spares that have been idle for quite some time. If you are replacing a valve with a new one that has been sitting outside for more than a year or even through extreme changes of weather, you are advised to test the valves before fixing them into the line.

When you are using a valve in a bypass while doing maintenance. Experts will always put a valve in a bypass pipeline as they do their maintenance on the mainline. In case these bypass valves have been idle for more than a year or rather have been in extreme changes of weather, they should always have a test before they are installed.

When you send a valve in order to be repaired. Any time you have an API valve repaired, maybe since it is leaking or not functioning well, the valve has to be tested again before you put it back into service on your line.

Types Of API 6D Valves

- Ball Valves

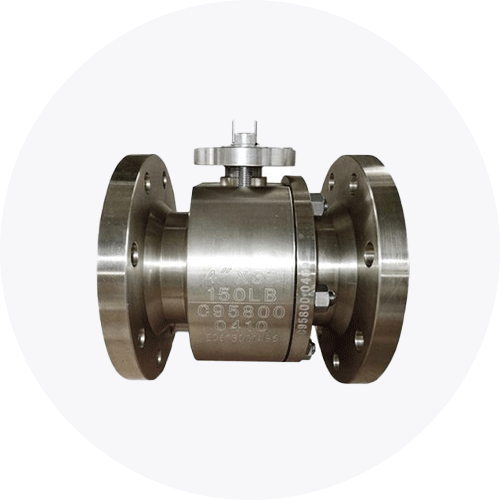

Source: https://en.siovalve.com/product-category/ball-valves/

API 6D Ball valve has a rounded hollow designed device used for on-and-off service. The ball is always in the path where fluid follows from. since this API 6D ball valves are rounded, either of its sides can be the inlet allowing flow to come through either of the direction and can as be used for changing the flow direction of the fluids.

It is important to source them from API 6d high pressure ball valves manufacturers who prioritize quality over cost. Best quality ball valves will serve the intended purpose for a longer time.

- Check Valves

Source: https://www.pinterest.com/pin/713398397227262568/

Check valves are majorly used in oil and gas pipelines to prevent any backflow of oil or gas. These check valves have a bolted cover and a clapper that swings freely. The clapper is mainly used to control the flow of fluids in the pipes when turned on and off.

- Gate Valves

Source: https://en.siovalve.com/product-category/gate-valves/

API 6D gate valves are customed to use pressure for tight cover on the top side when high pressure occurs. Internal springs have a sealing of low pressure as they help in pushing seat rings against the gates. API 6D high pressure steam valves are ideal in the transportation of gas, and oil products and their valves are made of different types of materials to meet your project needs.

Conclusion

It is important to have pressure valves inspected and tested before they are considered for use. Valves that have stayed in the store for a longer time will have to undergo a testing process since they might not perform the intended purpose perfectly. Always remember to use each valve for its intended function.