fire valve

mil control valve

boiler blowdown valve

Valve controls the flow of air or fluids through pipes or tubing, and it’s all too easy to overlook them until something bad happens. On the other side, valve maintenance can assist prevent problems from occurring in the first place.

We are going to look at the types of valves in piping and their applications. Keep Reading!

Table of Contents

Gate Valves

Globe Valves

Butterfly Valves

Control Valves

Ball Valves

Pneumatic Valves

What are Valves?

Source: https://unsplash.com/photos/TFgLjR9TAEM

It’s likely that you already know this. However, it is not harmful to refresh one’s memory.

A valve is a device that opens, closes, or partly obstructs fluid flow to monitor, control, or guide the flow of a fluid. Isn’t it a little complicated? Let me simplify this even more. A valve is a mechanical device that regulates fluid flow and pressure in a system or procedure. In a nutshell, it regulates flow and pressure.

How Valves Work

Source: https://unsplash.com/photos/wQfV9njQxW4

Gases and liquids are both regulated by valves. If your stove has a gas cooktop (hob), the controls that switch the gas on and off are called valves. When you raise the temperature, you’re opening a valve that permits more gas to enter the pipe. With a larger flame, more gas burns, resulting in more heat.

Any equipment that uses liquids or gases is almost certain to have valves. Every time the drum flushes out, a valve in your clothes washer turns the water flow on or off. In the chambers of your car engine, there are also valves that open and close numerous times each second to admit air and fuel while also allowing burned exhaust fumes to exit.

Purpose of Valves

Source: https://unsplash.com/photos/nN5L5GXKFz8

Valves serve the following purposes:

- Depending on the state of the valve, it can initiate or halt the flow.

- Controlling the flow and pressure in a pipe system

- Managing the streamlines in a pipe system

- Within a pipe system, regulating flow rates

- Mitigating pressure or vacuum in a piping system to improve security.

Type of Gate Valves and Their Applications

Source: https://www.pinterest.com/pin/715439090809758219/

In any procedure machinery, the most popular form of valve is a gate valve. It’s a linear motion valve that allows you to start or stop the flow of fluid. These valves are either fully open or totally closed when in service. Gate valves are employed in practically every fluid service, including air, fuel gas, feedwater, steam, lubricating oil, hydrocarbons, and just about anything else. The gate valve ensures a reliable shutdown.

Plugs normally close the valve on both the upstream and downstream faces, whereas plates typically only seal the upstream face. Wedges come in various shapes and sizes to help decrease or accommodate sealing surface wear.

Types of Gate Valves

- Solid Wedge Gate Valves

- Flexible Wedge Gate Valves

- Split Wedge or Parallel Disks Gate Valve

- OS & Y gate valve or Rising Stem Valve

- Non-rising Stem Gate Valve or Insider Screw Valve

Application of Gate Valve

- Gate valves are ideal for high-temperature and high-pressure applications.

- They’re employed in applications that require on-and-off switching.

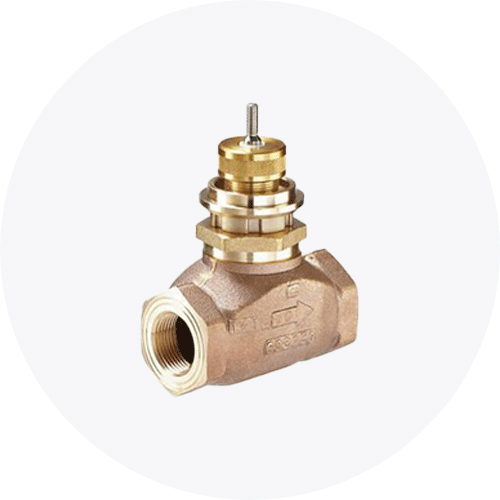

Types of Globe Valves and Their Applications

Source: https://www.pinterest.com/pin/715439090809756949/

The globe valve is used to control, halt, and start fluid flow. Globe Valves are employed in systems where there is a need for both flow control and leak sealing. In comparison to a gate valve, a globe valve provides superior shutoff and is more expensive.

The following are the many types of Globe Valves:

- Z types

- Y types

- Angle types

Application of Globe Valve

- Throttling is the primary function of global valves. They can be thought of as general-grounds flow control valves with a high-temperature use.

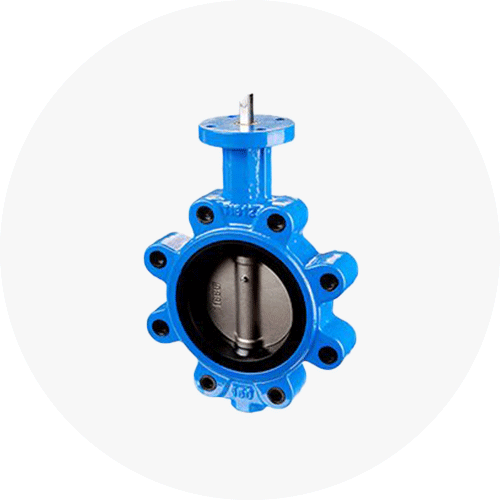

Types of Butterfly Valves and Their Applications

Source: https://www.pinterest.com/pin/985231158768918/

A butterfly valve is a motor-driven valve with a 90-degrees-turn that is used to pause, adjust, and initiate flow. The body of the butterfly valve is short and round. Butterfly valves are ideal for big valve operations because of their compact, lightweight design, which takes up far less space than conventional valves.

Types of butterfly valves include:

- Triple Offset Butterfly Valves

- Zero Offset Butterfly valves

- Double Offset Butterfly Valves

- Butt Welded Types Ends

- Lug Type End

- Wafer Type Ends

- Flanged Ends

Application of Butterfly Valves

- Butterfly valves are commonly utilized in the pharmaceutical, chemical, and food processing industries.

- They’re designed to handle corrosive liquids at low temperatures and pressures.

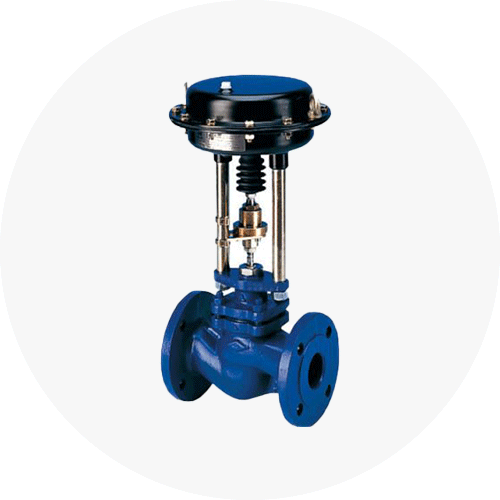

Type of Control Valves and Their Applications

Source: https://www.pinterest.com/pin/501236633549857372/

A control valve is a valve that regulates fluid flow by changing the size of the fluid flow in response to a controller command. This allows for direct regulation of flow rate and, as a result, process variables including tension, temp, and liquid level.

A valve body, actuator, positioner, and accessories make up a control valve installation. A bonnet assembly and trim pieces are included in the body. Its design can endure fluid static pressure and differential pressure while also allowing fluid flow, providing pipe-connecting ends, and supporting seating surfaces and a valve closure part.

Actuators are tools that offer the energy to open and close valves. They can be pneumatic, hydraulic, or electrically operated. To retain a preferred set-point, positioners track and regulate real actuator mobility.

Types of control valves

Control valves are categorised into two broad categories:

- Linear Motion Control Valves

- Rotatory Control Valves

Application of Control Valves

Control valves are mostly typically used for controlling procedure variables such as pressure, temperature, and liquid level.

Type of Hydraulic Valve and Their Applications

Source: https://www.pinterest.com/pin/297167275420693945/

Hydraulic valves come in various forms, including ball, butterfly, bypass relief, check, needle, diverter, regulating, pilot-operated, proportionate, and unidirectional. These hydraulic valves can be divided into three categories from a general viewpoint:

- Hydraulic Pressure Control Valves

- Hydraulic Flow Control Valves

- Hydraulic Directional Control Valves

Application of Hydraulic Valves

A hydraulic valve is a device used to control the flow of fluids. Waterworks valves are a specific example of industrial faucets since they have some distinctive characteristics and hence deserve to be treated independently.

1. Pressure Reducer

Source: https://www.pinterest.com/pin/246431410849662355/

The pressure reduction valve is a hydraulic control valve whose mission is to decrease the highly pressurized upstream of the valve to a fixed threshold lesser value downstream, irrespective of pressure fluctuations above or variations in flow and demand in the line.

2. Pressure Sustainer

Source: https://www.pinterest.com/pin/730990583240482247/

When you require a minimum pressure downstream or wish to lessen water pressure that is blowing up, the hydraulic pressure sustaining valve is used. Irrespective of variations in flow or pressure downstream, these valves are intended to keep a minimal pressure upstream.

The valve is controlled by a two- or three-way pilot that allows the valve to fully open when the pressure upstream exceeds the preset pressure. The valve will stay closed if the pressure is lower.

3. Reductive Valves and Pressure Sustainer

Source: https://www.pinterest.com/pin/230668812454154328/

When force is needed downstream sans disturbances, a reducing sustaining hydraulic valve is employed because it prevents pressure drops and overpressures. It is a valve that is controlled by a two-pilot system. A pilot maintains a steady pressure upstream, while the other acts as a pressure reduction to a certain level. The valve continuously opens or closes to maintain the proper preset pressures.

4. Flow Limiter

Source: https://www.pinterest.com/pin/637329784773781407/

When you wish to control the flow of water that feeds the valve, you use a flow control valve.

Irrespective of pressure variations upstream, the valve controls the flow downstream to a predefined value. If the flow rate is less than the preset value, the valve fully opens.

This valve is normally slightly open to allow a continuous flow downstream and is activated by the system’s pressure. Overconsumption, pressure drop, and supply to other deficits are all avoided with this type of valve.

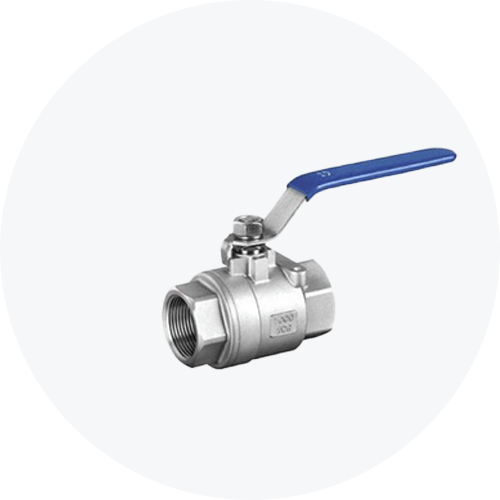

Type of Ball Valves and Their Applications

Source: https://www.pinterest.com/pin/1068479080314155205/

A right angle-turn rotary motion valve with a ball-shaped disk to stop or start the flow is known as a ball valve. The majority of ball valves are faster, requiring a 90° turn of the valve handle to activate. A gate valve of a similar size and rating is thinner and lighter than a ball valve.

The different types of ball valves include:

- Top Entry

- Side Entry or Split Body

- Three-piece body

- Floating Ball Valve

- 3 Way Ball Valve

- Trunnion Mounted Ball Valves

Applications of Ball Valves

- Ball valves are used to control the flow and pressure of corrosive fluids, slurries, regular liquids, and gases, as well as to shut them off.

- They’re employed in the oil and gas industry, but they’re also used in a variety of other industries, including industrial, chemical storage, and even residential applications.

Type of Pneumatic Valves and Their Applications

Source: https://www.pinterest.com/pin/777433954426126900/

Hydraulic valves are mechanical gadgets that control the flow of fluid inside a hydraulic system or circuit. They can be used to totally shut down a line, reroute pressurized fluid, or control the flow rate to a specific region. These valves are available in a variety of styles and can be operated manually or automatically via physical, mechanical, pneumatic, hydraulic, or electrical actuation.

Hydraulic valves must be able to handle high fluid pressures since many hydraulic systems operate at pressures of 3,000 psi or higher. As a result, they are frequently made of steel, iron, or other metals with sufficient strength to endure prolonged functioning under pressure.

Types of Pneumatic Valves

- Two-Ways Directional Control Pneumatic Valve

- Three-way Directional Control Pneumatic Valve

- Four-Way Directional Control Pneumatic Valves

- Spring offset Pneumatic Valves

Application of Pneumatic Valves

- For industry, secure and accurate control is essential.

- For medical purposes, pneumatics ensures cleanliness.

Conclusion

Well, that sums up the types of piping with all the lists. For more and better quality valves, SIO is the right place for you. Contact us for any enquiries and we assure you that we’ll be able to help. Best of luck!