When it comes to a critical service valve, you want the best

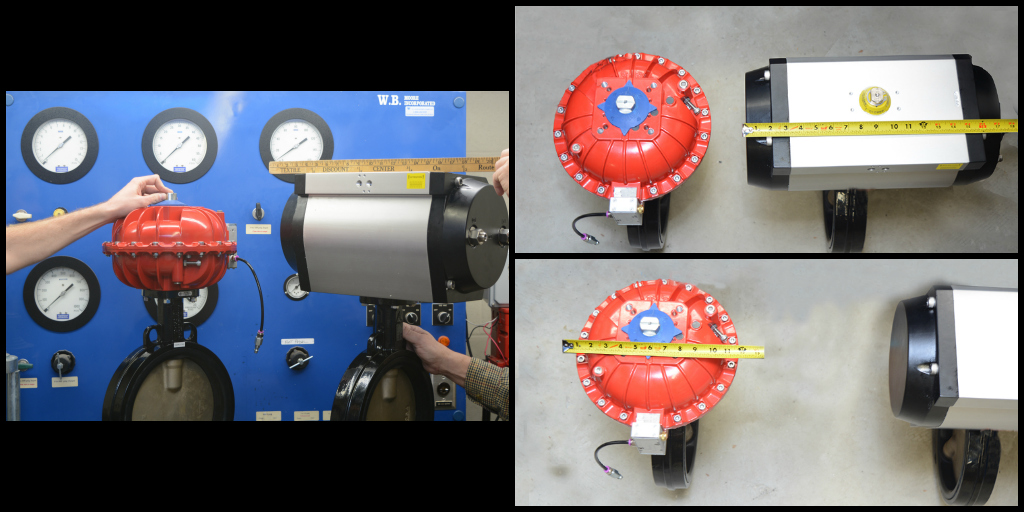

valve actuator you can buy. For decades, rack & pinion designs have dominated the field. However, recently vane actuation have begun to take a significant portion of the marketplace; this is due impart to its versatility and compact design. Regardless, the question remains, “which is the better design, and the greatest ROI?” The answer to that question requires considering more than a name brand, quality, or price–it requires a complete understanding of design difference, and what that means in the long run. Once this difference is established, then you can decide which design will best fit your application.

How Vane Actuation and Rack and Pinion Actuators Work

- Rack & Pinion: A rack & pinion actuator is made up of three major parts. There are two opposing pistons–each with its own set of gear teeth–known as racks. Both racks are set against a centered pinion gear. The racks move back and forth, causing the pinion to rotate clockwise and counter-clockwise.

- Vane Actuator: Vane actuators do not rely on this linear to rotary conversion. Instead, there is only one moving part–the internal vane–that is powered by inlet air.

How to Compare Rack & Pinion and Vane Actuation

Both designs perform the same job, but in different ways. Linear-to-rotary conversion requires more working parts: “O” rings, seals, and springs. To its credit, the rack & pinion design is tried and true. Unlike vane actuation, the rack & pinion has been around for decades; however, because of it many parts, rack & pinion seem to provide more opportunities for failure and breakage. An actuator is no small investment; thus, you want an actuator that provides longevity and versatility. Vane actuators are less complicated and have only one moving part; thus, a vane actuator’s longevity may be measured by up to 4 times as many millions of operations. In addition, the action of a vane actuator can be set/reset easily from air-to-open and air-to-close by simply adjusting the solenoid valve. That in itself is

very difficult (if not impossible) to do with a traditional rack & pinion. The rack & pinion would have to be completely disassembled and then re-assembled, which is simply no easy task.

Easytork Actuators

Now that you have some understanding how vane actuators and rack & pinion actuator work, you may be interested in trying out a vane actuator, but you’re unsure of which manufacturer to try. The pros at ValveMan believe

Easytork vane actuators win hands down. Easytork spring less pneumatic actuators are high performance, quarter turn rotary systems, featuring a patented aluminum vane body with an integral air reservoir they boast the longest life cycle at the lowest lifetime cost.

Easytork vane actuators (EVAs) are also the most compact on the market today, and will mount to almost any valve. Vane seal is pre- lubricated with grease in the plant, eliminating re-lubrication (under normal operating conditions). Standard operating temperature runs between -4°F to 176°F. Easytork actuators operate in the double acting principal for either double-acting or fail-safe functions. This eliminates corrosion from external environments, as there is zero vacuum effect to pull it in. And while clean dry air is the anticipated supply media, other inert gases such as natural gas, nitrogen, and argon may be used. In addition, thinned hydraulic oil may also be used.

Easytork easily leads the competition when it comes to vane actuation. Rugged, reliable, and state-of-the-art, EVAs are the next generation of fail-safe actuators and truly worth the investment.

If you have enjoyed this article from our

valve store and would like to read another, you might try:

- Introducing Bonomi Solenoid Valves

- What is the Difference Between Lug and Wafer Type Butterfly Valves?

- What is a Piggable Valve?