Valves are integral components in various industries, controlling the flow and pressure of fluids within a system. From household plumbing to complex industrial processes, valves ensure the proper management of liquid and gas flows, safeguarding system efficiency and safety. This article delves into the types of valves, their applications, and their importance, with a particular focus on how they interact with geomembrane systems.

What Are Valves and How Do They Work?

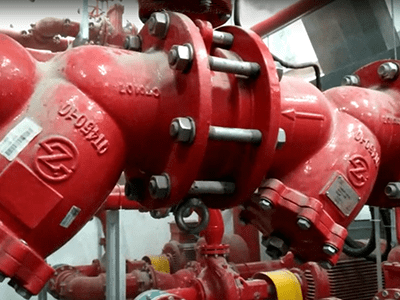

Valves are mechanical devices used to control the flow and pressure of fluids (liquids, gases, or slurries) within a pipeline or system. Their primary function is to either permit or restrict the flow of the fluid. By adjusting the valve’s position, you can regulate the flow rate, direct it to different channels, or completely shut it off. This is crucial for maintaining control over various processes, ensuring operational safety, and optimizing performance.

What Are the Different Types of Valves?

The main types of valves include:

- Gate Valves: Used for fully opening or closing the flow. Common in water distribution and wastewater systems.

- Ball Valves: Feature a spherical disc that controls flow. Ideal for applications requiring quick shutoff.

- Butterfly Valves: Employ a rotating disc to control flow. Suitable for large volume flows with minimal pressure drop.

- Check Valves: Prevent backflow, ensuring that fluids flow in one direction. Often used in pumps and pipelines.

Each type of valve is chosen based on its suitability for specific applications, such as pressure control, flow regulation, or backflow prevention.

How Do Valves Interact with Geomembrane Systems?

In systems utilizing geomembranes, such as landfill liners or water containment systems, valves are crucial for managing the flow of liquids within the system. Geomembranes are synthetic liners used to control fluid migration and protect underlying soil or structures. Valves help regulate the drainage or leachate collection systems associated with geomembranes, ensuring proper fluid management and preventing overflow or leakage. This coordination is essential for maintaining the integrity and functionality of the geomembrane system.

What Factors Should Be Considered When Selecting a Valve?

When selecting a valve, consider the following factors:

- Fluid Type: Different valves are suited for different fluids, whether they are corrosive, viscous, or particulate-laden.

- Pressure and Temperature: Ensure the valve can withstand the operating pressure and temperature of the system.

- Flow Control Requirements: Choose a valve that offers the appropriate level of control, whether it is a simple on/off valve or one that provides fine-tuned flow regulation.

- Material Compatibility: The valve material must be compatible with the fluid to prevent damage or contamination.

By evaluating these factors, you can select a valve that ensures optimal performance and longevity in your system.

Valves are vital components in fluid management across various industries, controlling flow, pressure, and direction of fluids. Understanding the different types of valves and their applications helps in selecting the right valve for your needs. In systems that incorporate geomembranes, such as waste containment or water reservoirs, valves play a crucial role in managing fluid flow and maintaining system integrity. By considering factors such as fluid type, pressure, and material compatibility, you can ensure that the valve selected will perform efficiently and effectively within your system.