DC explosion proof motors are specialized electrical devices designed to operate safely in hazardous environments where flammable gases or dust are present. These motors provide reliable performance while minimizing the risk of ignition, making them essential in industries such as oil and gas, mining, and chemical processing. This article delves into the key features, benefits, and applications of DC explosion proof motors, ensuring you have a comprehensive understanding of their role in maintaining safety and efficiency.

What are DC explosion proof motors?

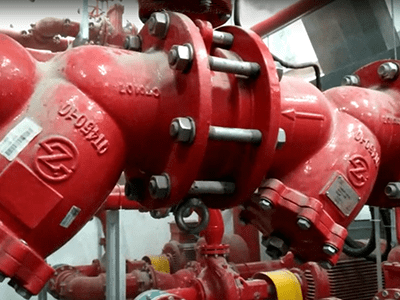

DC explosion proof motors are electric motors designed to prevent the ignition of explosive atmospheres. They feature robust enclosures that contain potential sparks or heat, ensuring safe operation in hazardous locations.

How do DC explosion proof motors differ from standard motors?

Unlike standard motors, DC explosion proof motors are constructed with specific materials and designs that can withstand explosive conditions. They include additional safety features, such as enhanced insulation and pressure-relief vents.

What industries benefit from using DC explosion proof motors?

Industries such as oil and gas, mining, chemicals, and pharmaceuticals benefit significantly from these motors. Their ability to operate safely in explosive environments makes them vital for processes where flammable substances are present.

Can DC explosion proof motors be used with other technologies, like geogrid systems?

Yes, DC explosion proof motors can be integrated with geogrid systems for various applications, including reinforcing structures in hazardous locations. This combination enhances both stability and safety in challenging environments.

DC explosion proof motors are crucial for ensuring safety and efficiency in industries exposed to hazardous conditions. Their specialized design prevents ignition, making them indispensable in applications where flammable substances are present. Understanding their features and benefits, along with their compatibility with technologies like geogrid systems, is essential for optimizing safety in critical environments.