industrial valve

industrial pipe and valve

industrial valve manufacturers

industrial ball valve

1. The difference between globe control valve and gate valve structure

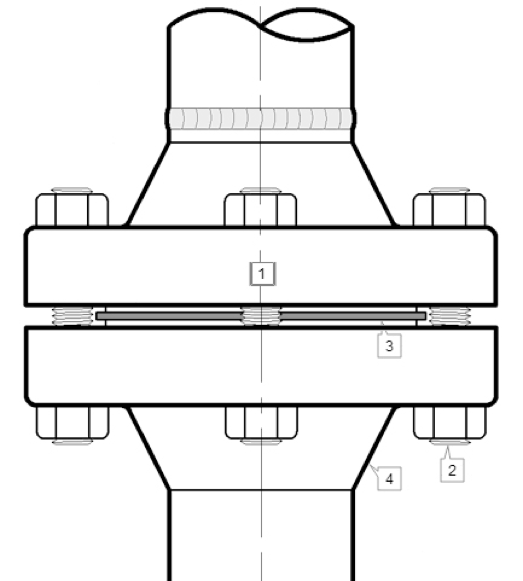

When the installation space is limited, you should pay attention to the selection. The gate valve can be tightly sealed with the sealing surface by the medium pressure, so as to achieve the effect of no leakage. When opening and closing, the valve core and valve seat sealing surfaces always contact and rub against each other, so the sealing surfaces are easy to wear. When the gate valve is close to closing, the pressure difference between the front and rear of the pipeline is large, which makes the sealing surface wear more seriously. The structure of the gate valve is more complicated than that of the globe control valve. From the appearance, the gate valve of the same diameter is higher than the globe control valve, and the globe control valve is longer than the gate valve. In addition, the gate valve has an open rod and a dark rod, and the globe control valve does not.

2. The difference between the working principle of globe control valve and gate valve

The opening and closing method of the globe control valve is an open rod type, that is, when the handwheel is turned, the handwheel will rotate and lift with the valve stem. The gate valve is to rotate the handwheel to make the valve stem move up and down, and the position of the handwheel itself remains unchanged. The flow rate is different. Gate valves need to be fully open or fully closed, while globe control valves do not. globe control valves have specified inlet and outlet directions; gate valves have no inlet/outlet direction requirements. In addition, the gate valve only has two states of fully open or fully closed, the gate opening and closing stroke is large, and the opening and closing time is long. The movement stroke of the disc of the globe control valve is much smaller, and the disc can stop at a certain position during the movement, which plays the role of flow regulation. The gate valve can only be used for shut-off and has no other function.

3. The difference between the performance of globe control valve and gate valve

globe control valves can be used for shut-off and also for flow regulation. The fluid resistance of the globe control valve is large, and it is more laborious to open and close, but due to the short distance between the valve plate and the sealing surface, the opening and closing stroke is short. Since the gate valve can only be fully opened and fully closed, when fully opened, the flow resistance of the medium in the valve body channel is almost zero, so the opening and closing of the gate valve is very labor-saving, but the gate is far away from the sealing surface, and the opening and closing time is longer.

4. The difference between the installation and flow direction of globe control valve and gate valve

The flow effect of the gate valve is the same in both directions. There is no installation requirement in the inlet and outlet directions, and the medium can circulate in both directions. The installation of the globe control valve needs to be marked in strict accordance with the arrow direction of the valve body. There are also clear regulations on the inlet and outlet directions of the globe control valve. In the valve “three changes”, the flow direction of the globe control valve adopts a top-down method.

The shut-off valve is changed from low to high, and it is obvious that the pipeline is not the same level from the outside. The gate valve runner is on the horizontal line. The stroke of the gate valve is larger than that of the globe control valve. From the perspective of flow resistance, when fully open, the flow resistance of the gate valve is small, and the flow resistance of the load check valve is large. The flow resistance coefficient of ordinary gate valves is about 0.08~0.12, the opening and closing force is small, and the medium can flow in both directions. The flow resistance of ordinary globe control valves is 3-5 times that of gate valves. The spool of the globe control valve contacts the sealing surface when it is fully closed, so the sealing surface wears very little. Due to the large flow of the globe control valve with the actuator, attention should be paid to the adjustment of the torque control mechanism.

There are two ways to install the globe control valve, one is that the medium can enter from the lower part of the valve core. The disadvantage is that the driving torque of the valve is large, which is about 1 times that of the flow into the upper part. The axial force of the valve stem is large, and the valve stem is easy to bend. Therefore, this method is generally only suitable for small-diameter globe control valves.

Related News & Blog

How to Choose Correct butterfly Valves?

Electric actuators have different functions and types, which can be called electric valves when matched with valves. However, in the design and selection process, only focus on the parameters of the v…

The Structure and Application of Gate Valves

1. Structural form of gate valveIndustrial valve is a common valve in electric valve products. The main gate valves of gate valve manufacturers have four structures: wedge type elastic single gate val…

Monel Valves in Marine Engineering: Defying Saltwater Corrosion

Marine engineering is a field that demands durability, resilience, and unwavering performance. Operating in saltwater environments, ships and offshore structures are exposed to the relentless corrosio…